MODO: Seelong-Carton Apertura Macchina SLCO-01A

VANTAGGI 1. : Applicabile per una varietà di dimensioni dei cartoni

VANTAGGI 2. : Processo di apertura del cartone, sagomatura, pieghevole e attaccatura di nastri adesivi in 3 secondi;

VANTAGGI 3.: Pieghevole e sigillatura inferiore senza fermarsi sul nastro trasportatore;

VANTAGGI 4.: Adotta la macchina di controllo dell'interfaccia PLC e MAN-Machine, facile da usare, semplice da manutenzione

APPLICAZIONE: Ampiamente usato per imballaggi alimentari, pasticceria, medicina, cosmetici, vari merci, ecc

Oggetto numero:

Case Erector KXJ-01AOrdine (MOQ):

1 PCPagamento:

T/T; L/C; WESTERN UNIONOrigine del prodotto:

CHINAPorto di spedizione:

SHANGHAI; SHENZHEN; NINGBO; QINGDAO; GUANGZHOUTempi di consegna:

15-30DAYSPeso:

1000KGSeelong- Apertura di cartone SLCO-01A

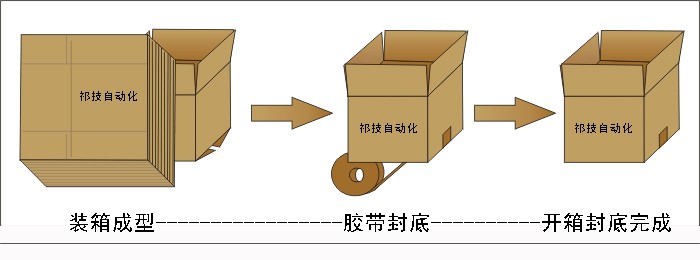

Diagramma di formazione di cartone:

Adotta la tecnologia avanzata internazionale e utilizzano parti importate, componenti elettrici. È ampiamente utilizzato nel cibo, medico, bevande, tabacco, automobilistico, cavo, elettronica e altre industrie nazionali.

Caratteristiche:

1. È applicabile per una varietà di taglie di cartoni, se si desidera modificare le specifiche di cartone, è semplice regolare manualmente.

2. La macchina può finire il processo di apertura di cartone, sagomatura, piegatura e attaccare nastri adesivi in 3 secondi.

3. Piegatura inferiore e sigillatura senza fermarsi sul nastro trasportatore.

4. Adotta la macchina di controllo dell'interfaccia del PLC e dell'uomo, facile da usare, semplice da manutenzione, che è essenziale per l'apparecchiatura della linea di assemblaggio per realizzare la produzione automatica di massa.

5. Sostituzione del manuale del lavoro per questa macchina potrebbe ridurre almeno 2-3 lavoratori di imballaggio, salvare il 5-10% di materiali, migliorare l'efficienza del 30% e rendere l'imballaggio più standardizzato.

6. Questo tipo di cartonizzazione è ampiamente utilizzato per imballaggio prodotti alimentari, pasticceria, medicina, cosmetici, merci vari, ecc.

Parametri tecnici principali:

Velocità di ravvigionamento | 8-12Carton / min. |

Volume di stoccaggio del cartone | 100 pz (1000 mm) |

Dimensioni del cartone | L (250-450) * W (150-400) * H (100-400) mm (La dimensione minima non può apparire allo stesso tempo) |

Fornitura elettrica e alimentazione | 220V / 50Hz, 200W |

Pressione dell'aria | 6 kg / cm2. |

Consumo d'aria | 450nl / min. |

Dimensioni esterne | L2000 * W1900 * H1450mm |

Dimensioni del nastro adesivo | 48,60,75mm |